Product Introduction:

Mecru HPG multi-cylinder cone crusher is mainly used in the second-stage intermediate crushing and third-stage fine crushing in metal mines and sand and gravel aggregate processing. Crusher safety, adjustment, and locking all use hydraulic devices, so it has what other crushers do not have. It is convenient to adjust the discharge port, and the overload coefficient is small when passing non-crushed objects. It is easy to take out the non-crushed objects that are blocked in the crushing cavity.Product Advantages:

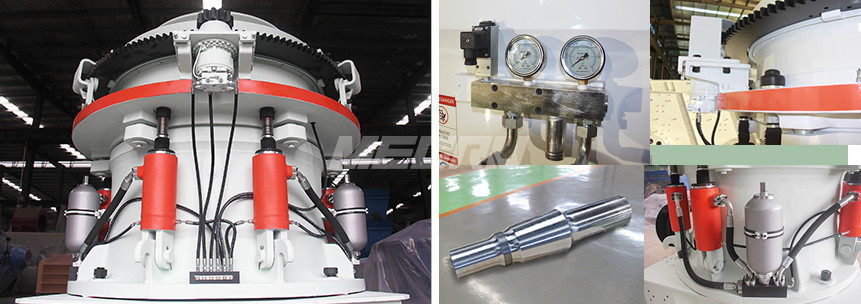

1. Hydraulic devices are used for insurance, adjustment and locking of the crusher. It is convenient to adjust the discharge port and has a small overload coefficient when passing non-crushed objects. 2. Mecru continuously optimizes the equipment and cavity type, which not only improves the efficiency of lamination crushing, but also has high crushing efficiency, but also has low wear of vulnerable parts and reduces production costs. 3. The finished product has a cubic shape and high fine-grain content, which not only improves the quality of the finished product, but also reduces the production cost of the equipment and the entire system. 4. One machine can change different crushing cavity types. The machine is equipped with multiple medium crushing and fine crushing cavities. Only a small number of parts such as the corresponding cavity type liner can be replaced to convert the machine cavity type.

Working Principle:

The cone breaker moves the cone under the action of the eccentric sleeve to make a swing motion, which drives the broken wall to squeeze and grind the material between the wall and the rolling mortar wall. According to the lamination theory, the material is subjected to forces in multiple directions, according to its own texture. It is crushed and polished to form stable stone particles, which fall from the swing gap of the crushing wall that meets the discharge requirements, and the rest of the materials continue to be broken until the discharge demand is reached.Product Parameters:

Technical parameters of HPG multi-cylinder cone crusher| Model | Cavity | Open side feeding size (mm) | Closed side feeding size (mm) | Min outlet size (mm) | Capacity (t/h) | Power (kw) |

| HPG100 | C1(Extra Coarse) | 175 | 140 | 19 | 45-100 | 90 |

| C2(Coarse) | 125 | 105 | 13 | |||

| M(Middle) | 100 | 70 | 10 | |||

| F1(Fine) | 71 | 50 | 9 | |||

| F2(Extra Fine) | 33 | 20 | 6 | |||

| HPG200 | C2(Coarse) | 235 | 190 | 19 | 65-250 | 160 |

| M(Middle) | 171 | 120 | 16 | |||

| F1(Fine) | 150 | 95 | 13 | |||

| F2(Extra Fine) | 116 | 70 | 8 | |||

| HPG300 | C1(Extra Coarse) | 265 | 230 | 25 | 85-440 | 220 |

| C2(Coarse) | 240 | 210 | 20 | |||

| M(Middle) | 190 | 150 | 15 | |||

| F1(Fine) | 145 | 105 | 11 | |||

| F2(Extra Fine) | 120 | 80 | 8 | |||

| HPG400 | C1(Extra Coarse ) | 360 | 290 | 30 | 135-625 | 315 |

| C2(Coarse) | 310 | 250 | 25 | |||

| M(Middle) | 260 | 196 | 20 | |||

| F1(Fine) | 182 | 110 | 13 | |||

| F2(Extra Fine) | 135 | 90 | 10 | |||

| HPG500 | C1(Extra Coarse) | 370 | 330 | 38 | 200-790 | 400 |

| C2(Coarse) | 320 | 290 | 28 | |||

| M(Middle) | 245 | 210 | 22 | |||

| F1(Fine) | 180 | 130 | 13 | |||

| F2(Extra Fine) | 150 | 95 | 10 | |||

| HPG800 | C1(Extra Coarse) | 450 | 352 | 38 | 265-1200 | 630 |

| C2(Coarse) | 373 | 298 | 32 | |||

| M(Middle) | 340 | 275 | 25 | |||

| F1(Fine) | 280 | 230 | 16 | |||

| F2(Coarse Fine) | 235 | 150 | 10 |